|

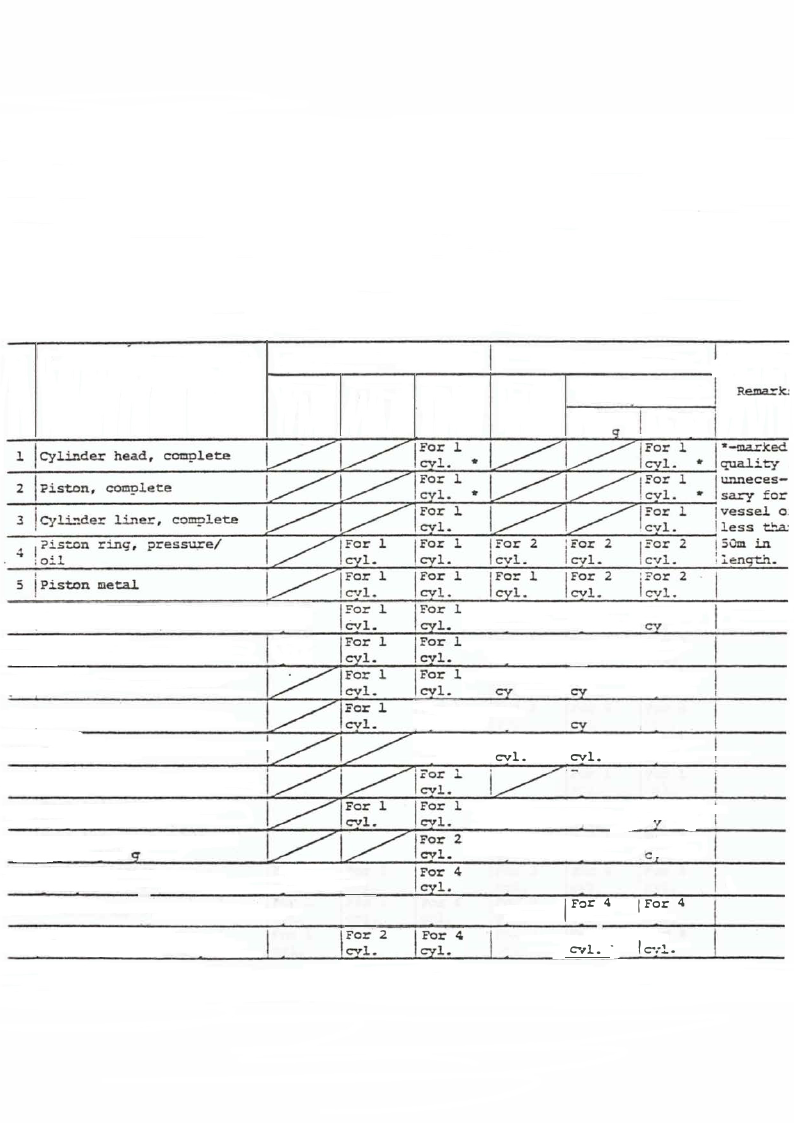

Fishing boat engine for Tonga Project |

|

1 Pages 1-10 |

▲back to top |

|

1.1 Page 1 |

▲back to top |

|

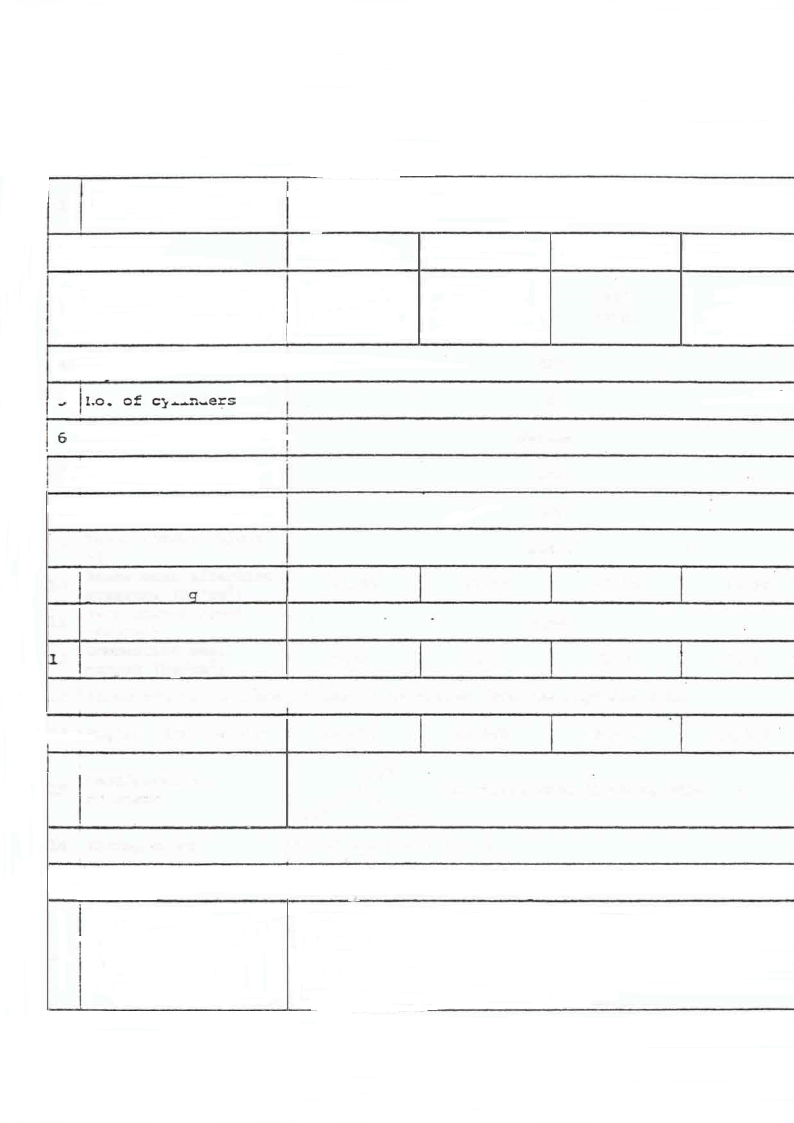

1.2 Page 2 |

▲back to top |

|

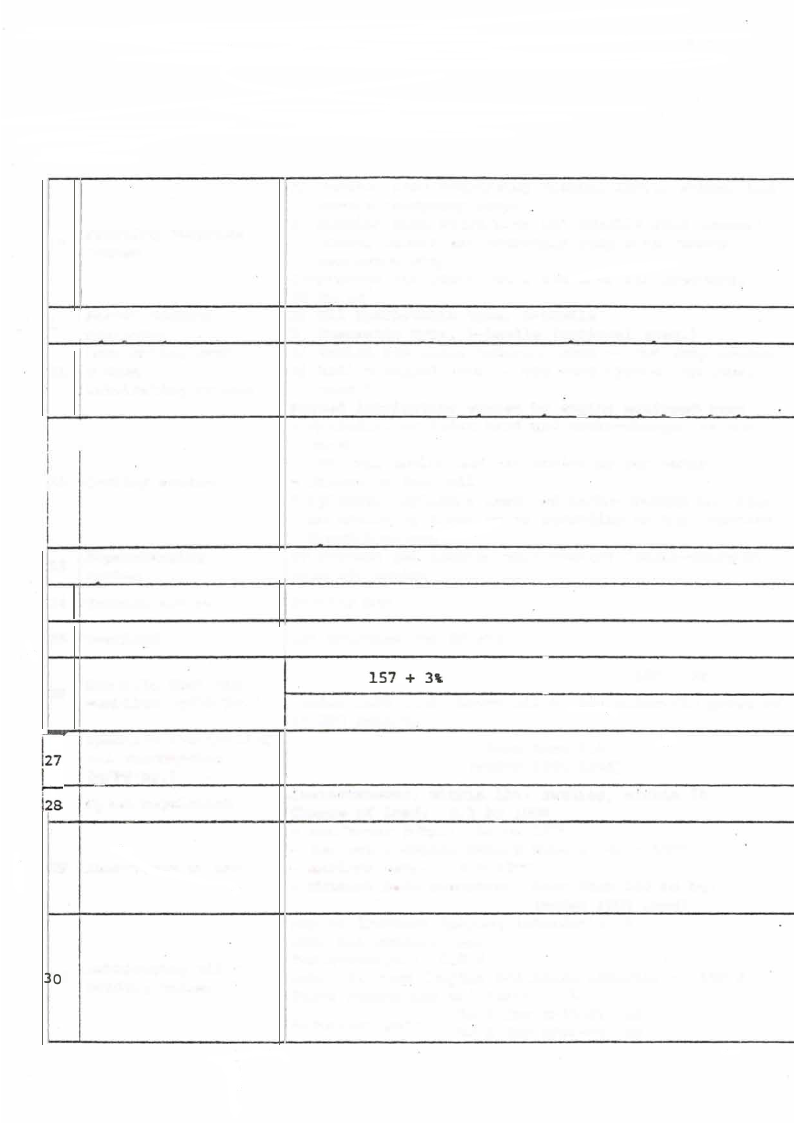

1.3 Page 3 |

▲back to top |

|

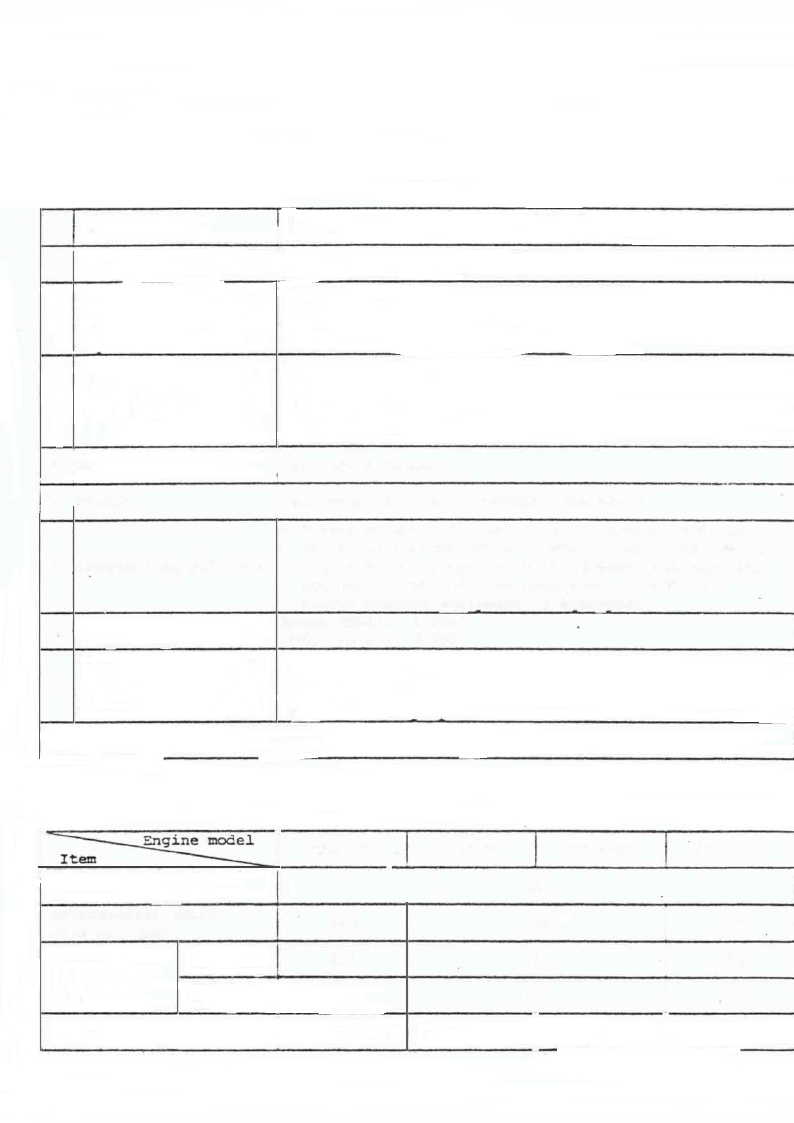

1.4 Page 4 |

▲back to top |

|

1.5 Page 5 |

▲back to top |

|

1.6 Page 6 |

▲back to top |

|

1.7 Page 7 |

▲back to top |

|

1.8 Page 8 |

▲back to top |

|

1.9 Page 9 |

▲back to top |

|

1.10 Page 10 |

▲back to top |

|

2 Pages 11-20 |

▲back to top |

|

2.1 Page 11 |

▲back to top |

|

2.2 Page 12 |

▲back to top |

|

2.3 Page 13 |

▲back to top |

|

2.4 Page 14 |

▲back to top |

|

2.5 Page 15 |

▲back to top |

|

2.6 Page 16 |

▲back to top |

|

2.7 Page 17 |

▲back to top |

|

2.8 Page 18 |

▲back to top |

|

2.9 Page 19 |

▲back to top |

|

2.10 Page 20 |

▲back to top |

|

3 Pages 21-30 |

▲back to top |

|

3.1 Page 21 |

▲back to top |

|

3.2 Page 22 |

▲back to top |

|

3.3 Page 23 |

▲back to top |

|

3.4 Page 24 |

▲back to top |

|

3.5 Page 25 |

▲back to top |

|

3.6 Page 26 |

▲back to top |

|

3.7 Page 27 |

▲back to top |

|

3.8 Page 28 |

▲back to top |

|

3.9 Page 29 |

▲back to top |

|

3.10 Page 30 |

▲back to top |

|

4 Pages 31-40 |

▲back to top |

|

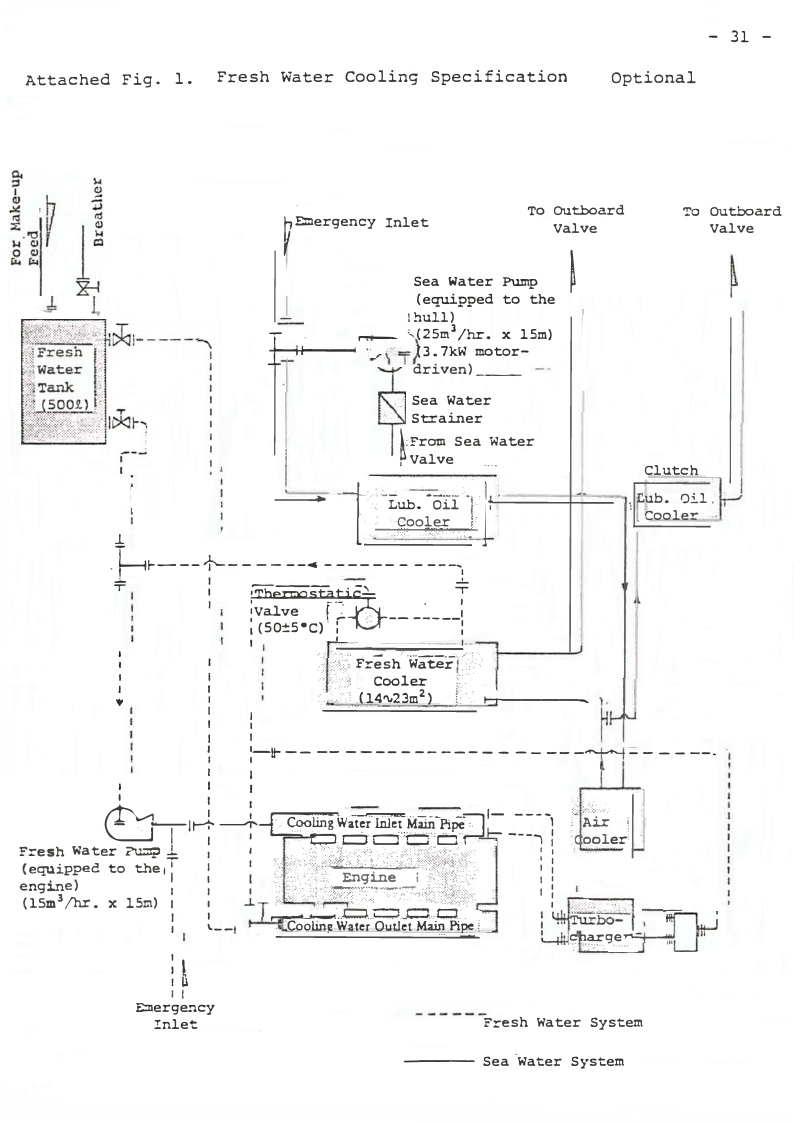

4.1 Page 31 |

▲back to top |

|

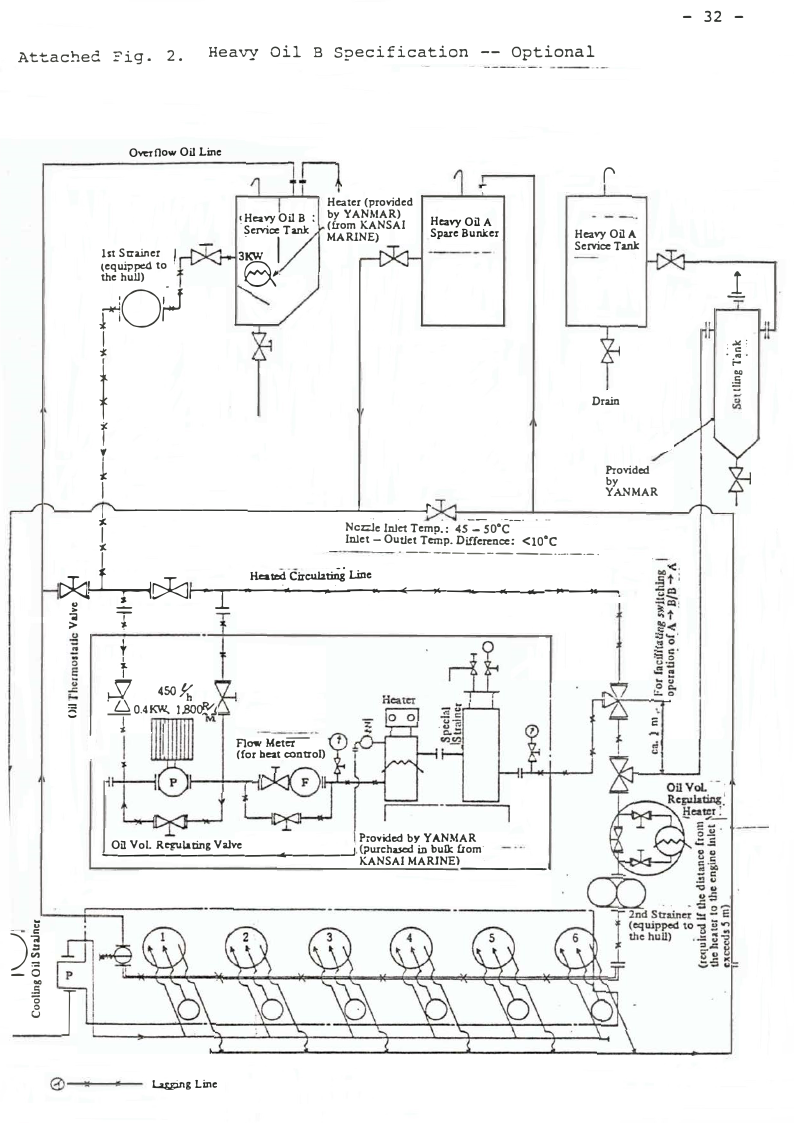

4.2 Page 32 |

▲back to top |

|

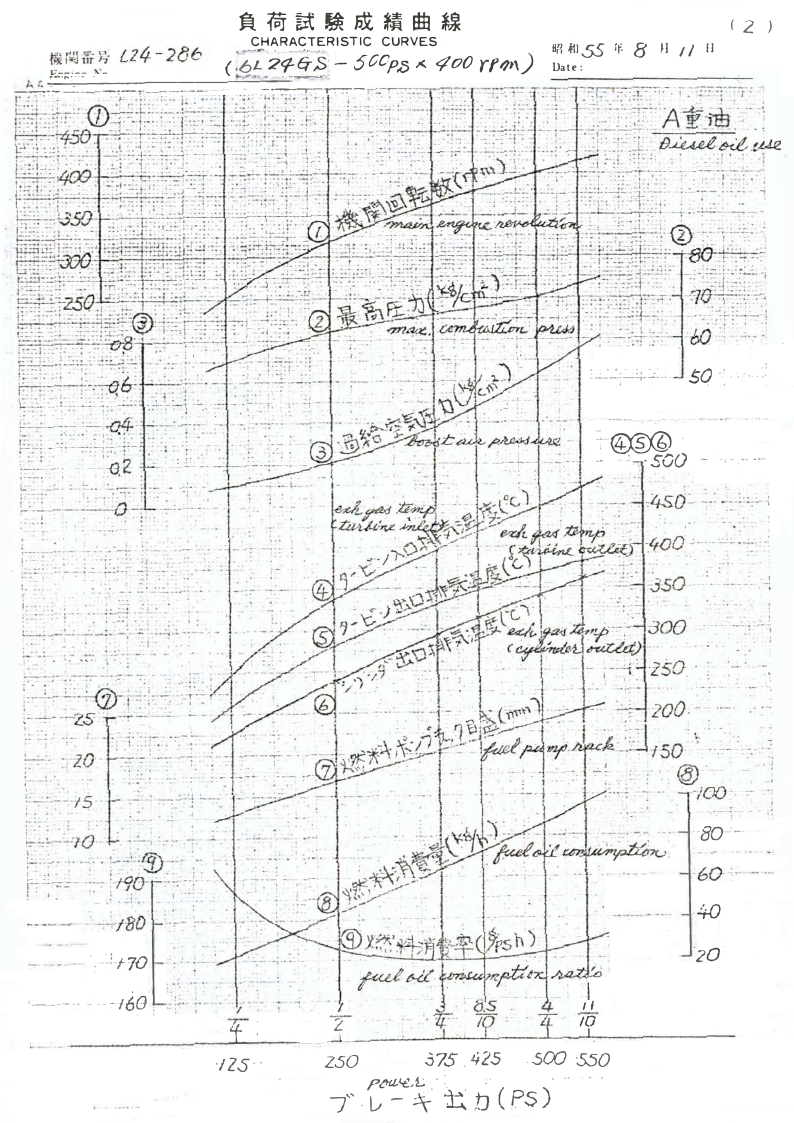

4.3 Page 33 |

▲back to top |

|

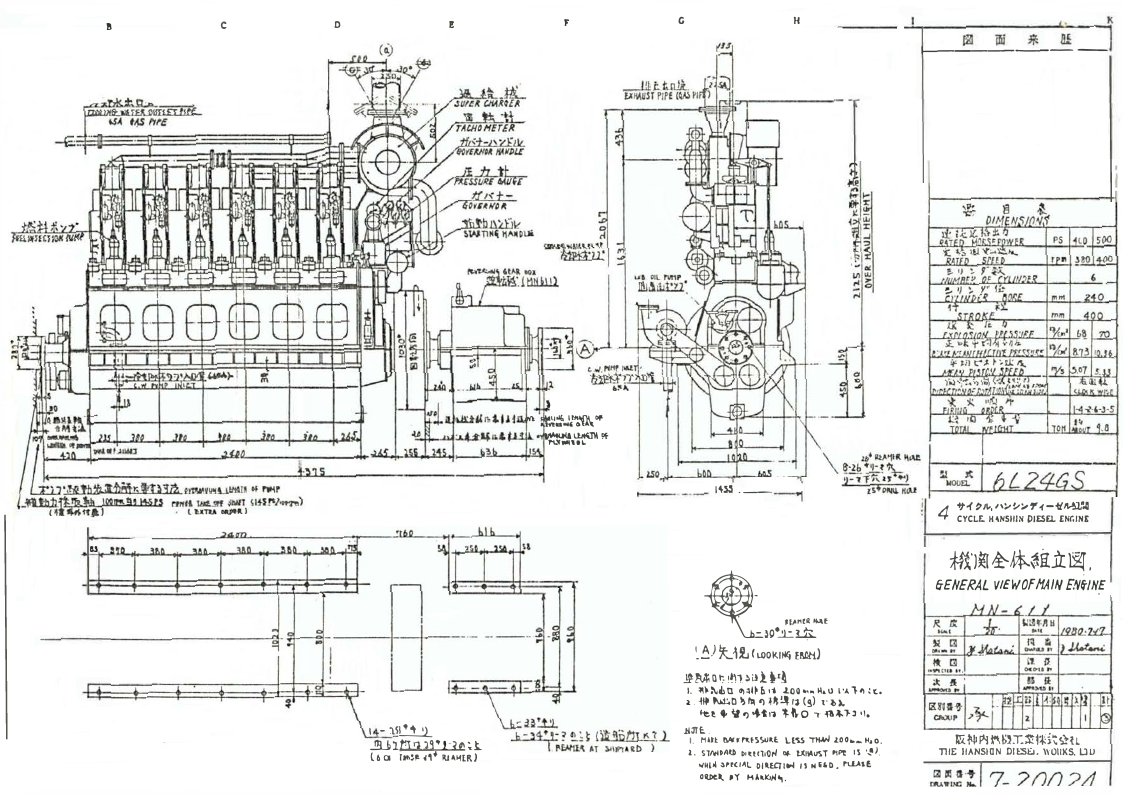

4.4 Page 34 |

▲back to top |

|

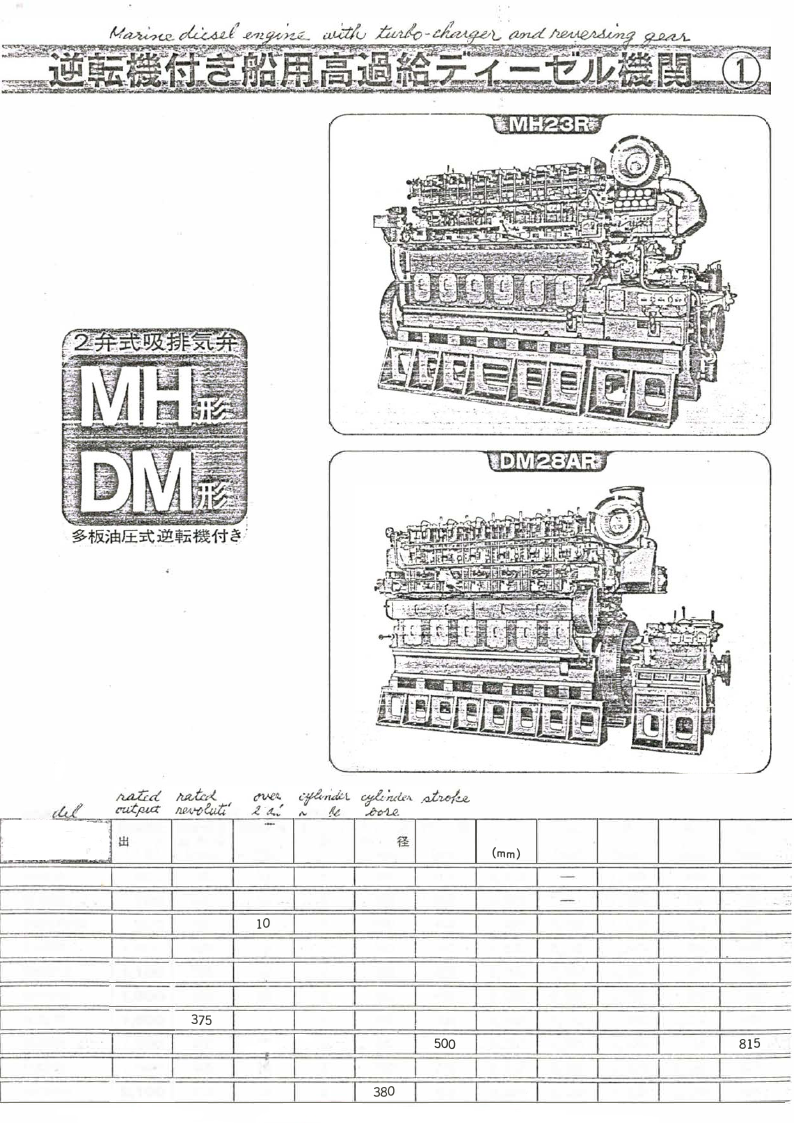

4.5 Page 35 |

▲back to top |

|

4.6 Page 36 |

▲back to top |

|

4.7 Page 37 |

▲back to top |

|

4.8 Page 38 |

▲back to top |

|

4.9 Page 39 |

▲back to top |

|

4.10 Page 40 |

▲back to top |

|

5 Pages 41-50 |

▲back to top |

|

5.1 Page 41 |

▲back to top |

|

5.2 Page 42 |

▲back to top |

|

5.3 Page 43 |

▲back to top |

|

5.4 Page 44 |

▲back to top |

|

5.5 Page 45 |

▲back to top |